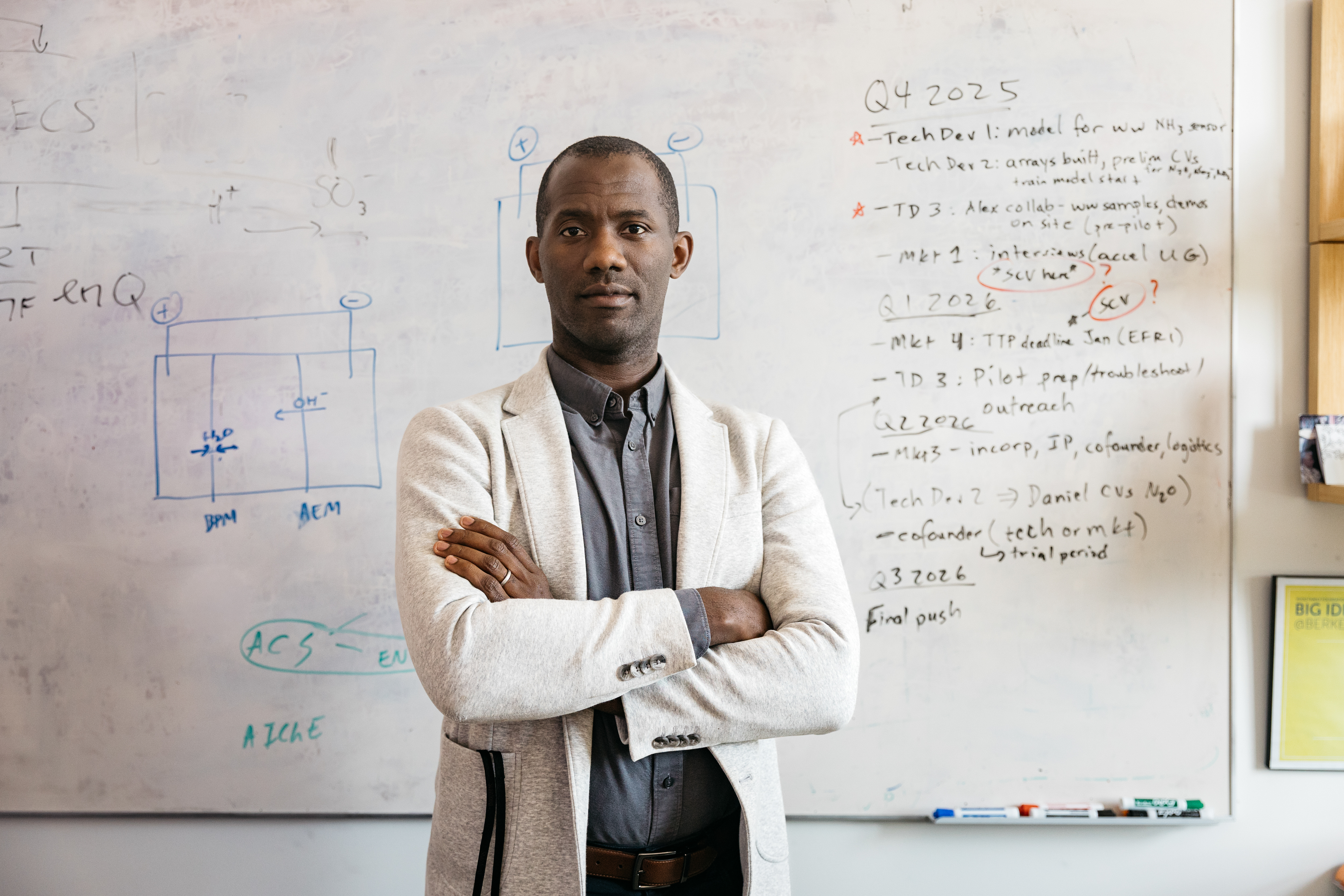

About William's Work

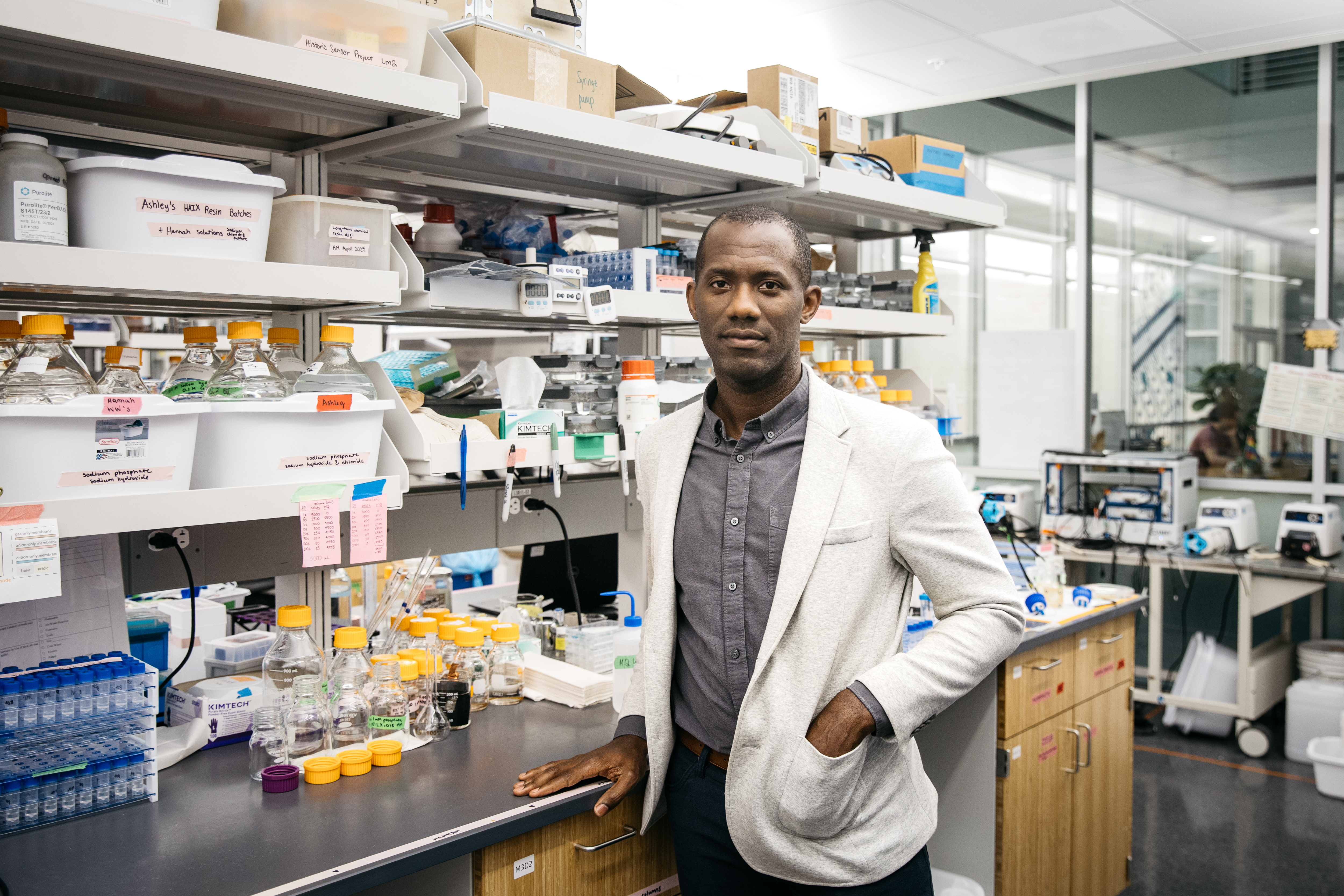

William Tarpeh is a chemical engineer developing sustainable and practical methods to recover valuable chemical resources from wastewater. Tarpeh’s research focuses on recycling nitrogen, sulfur, and phosphorus. His resource recovery technologies require minimal infrastructure and energy, and they offer opportunities for sustainably sourcing agricultural nutrients and industrial metals in a range of contexts.

Nitrogen-, sulfur-, and phosphorus-containing compounds are ubiquitous in municipal, agricultural, and industrial wastewater. In wastewater, these elements are harmful to the environment and human health, but they are also the basis of essential chemical products including fertilizer and household cleaners. Conventional methods of ammonia stripping, which removes nitrogen from wastewater, require significant energy and chemical inputs. Tarpeh has developed electrochemical-based processes to isolate nitrogen from wastewater using electricity and ion-selective membranes. His electrochemical reactors convert nitrogen in urine waste streams into ammonia-based products, and they can be tuned to produce ammonium sulfate, which is used in fertilizer, or ammonium hydroxide, which is used in household cleaners and industrial chemical production. Unrefined and mixed-source waste streams present additional challenges for resource recovery. The relatively low concentration of nitrogen amidst many other impurities makes it more difficult to efficiently extract and convert it. Tarpeh and colleagues have demonstrated an electrocatalyst-in-a-box (ECaB) that recovers ammonia directly from municipal wastewater. The two-stage reactor assembly first separates nitrogen compounds from wastewater. Electrocatalysis applied in a separate reactor compartment converts the concentrated nitrogen into ammonium sulfate. This technology offers the potential for a closed-loop system that allows local sanitation systems to manufacture needed chemicals. Tarpeh is also developing other technologies, like ligand-exchange adsorbents (materials that bind molecules to their surface) and polymer membranes, to recover resources with industrial applications, such as lithium and phosphorus.

Currently, Tarpeh is working to implement his technologies at scale, including in places with limited infrastructure. His pilot project in Kenya produced urine-derived fertilizers at lower cost than synthetic fertilizer. He and colleagues are also testing an ECaB system with agricultural run-off in California farm fields. If successful, the ECaB system would prevent nitrate pollution (which causes devastating algal blooms in waterways) and generate a sustainable, cost-effective source of fertilizer. Waste generation from humans, agriculture, and industry is an ever-growing challenge for environmental and public health. Tarpeh’s work is critical to reducing the harms of wastewater and sustainably generating chemicals that are vital to modern life.